The new take on Value Engineering: Where technology and fabrication converge for better building.

With new technology and manufacturing capabilities, Value Engineering is being redefined to represent building value into a project, rather than taking it out. Here, we explore the reasons why.

The term Value Engineering is traditionally defined* as “a systematic and organized approach to providing the necessary functions in a project at the lowest cost.” It promotes the substitution of materials and methods to cut cost. However, it is focused solely on the functionality of components and materials, rather than any physical attributes.

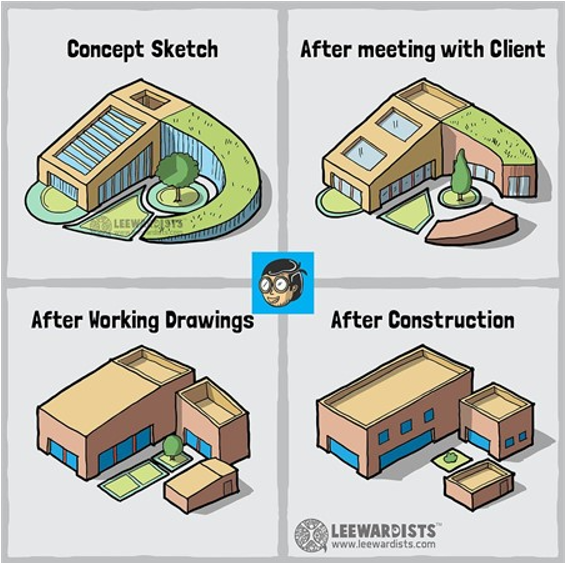

The aesthetic compromises of traditional Value Engineering.

The reality of this traditional approach to Value Engineering is neatly summed up in this cartoon strip from Leewardists.com.

With all the focus on reducing costs, the physical attributes of componentry and build approach are ignored. In short, aesthetics are of no consequence. This results in a finished build that fails to bring to life the design vision in the original concepts. Yet for project owners, these are often fundamental and the outcome can leave them frustrated, feeling short changed.

The new Value Engineering removes the compromises of old.

At Howick, we are part of a growing movement of people in the construction space who believe the traditional concept of Value Engineering should be up-ended. There must be more to it than simply removing cost. With modern methods of construction, it can be about engineering value in at the outset rather than removing it as the project progresses.

As stated by the host of the Beyond BIM Podcast, Michael Evans, Value Engineering is now “about delivering better projects, optimizing design, promoting teamwork and simplifying complexity.”

Advances in design and fabrication technology are the game changer.

It is the evolution and integration of design software and fabrication technology that has been the game changer. As Nick Coubray, Howick’s CEO, explains. “Howick machines are part of a new VE dynamic, contributing fast, accurate, precision fabrication capability that makes full use of the design software tools available.”

“At Howick, we are laser focused on being smarter with technology to build better. Integrating with the software tools that create generative designs, building information modelling, and the smart technology that drives fabrication is fundamental. All of this is central to the concept of the new VE picture.”

Of course, this does take a different approach to the build process, calling on everyone from the architects, to the engineers to the site crew to work collaboratively to optimize the efficiencies available. So how does this work in practice?

The adage “Measure twice, cut once” is truer than ever.

Essentially, it requires developers to build structures twice – first in a virtual, 3D world. Only once this is complete can the physical build commence.

Designers use generative software and computational design to work out the possibilities within set parameters, determine workflow and requirements. Fabrication technology – such as the Howick machines – then come into play to build prototypes and automate repeatable tasks.

Using this approach, design challenges can be solved quickly and cost-efficiently. Project plans that are so complete at the outset have the benefit of reducing risk throughout the construction phase. Any foreseen problems can be tackled at the planning stage, rather than being left to be solved onsite.

Construction components are then fabricated in order of play. They are dimensionally accurate from the outset, ready to be transported to site for just-in-time construction on site.

“Efficient 3D design, by people who know how to get the best out of fabrication technology, reduces the amount of material in a build. It dramatically improves onsite construction times, and makes the whole process more efficient with less risk of re-work.” Nick states.

Smart construction businesses using this approach are rewarded with healthier profit margins as well as happier clients. And of course, building owners are left with better buildings that are closer to the original vision on which they signed off.

Staying true to the design vision

Without value engineering the vision and the reality of a building can be two different things. The architect may well design an impressively complex structure, yet through the traditional build process, the end result is often something quite different.

With restrained budgets, it may not always be possible to achieve the exact outcome the architect envisions. However, using the right approach to value engineering with the benefit of computational and generative design software, and fabrication technologies like those of Howick, it is amazing how much can be achieved.

The new Value Engineering in action

In one example, a project undertaken by US company Studio Construction required the creation of a sculptured geometric gateway – a portal for a new medical clinic in Playa Vista, California. The design had no two matching panels, and its adjacent panels were set at varying angles.

Following through on the processes outlined above, it called for a complex design solution built first in 3D. Two Howick roll-forming systems (both dedicated frame and truss component manufacturing machines) were then put to work to output the components.

STUDIO founder Scott Mitchell says the use of these systems simplified an incredibly complex project and elevated the precision of its details.

The Portal project can also be considered a collaboration success story, with various companies working together to achieve a challenging goal - another important component of the new world of value engineering.

KHS&S (also involved in the Portal project) is another example of a specialist construction business working in the VE space. The business has a well-founded reputation for its capability in intricate and complex build projects. Projects of note include The Wizarding World of Harry Potter at Universal Studies, and Star Wars replicas in the Walt Disney World Resort.

* https://www.investopedia.com/terms/v/value-engineering.asp

Was this article insightful? Share it

January 2022 #Features