X-TENDA™ 3600

- Gauge Range

-

- Production Speed

-

- Dimensions L x W x H

-

Internal steel framing that fits. No matter what.

Frame any space fast with Howick's most versatile machine.

One of the greatest challenges with interior refits is that internal spaces are rarely, if ever, straight. For installers of steel framing systems, this means lost time and wastage due to the need to measure and trim components onsite.

Howick’s X-TENDA™ 3600 solves that problem with a breakthrough steel roll-forming system that manufactures telescopic framing for interior walls, ceilings and more. X-TENDA™ 3600 frames can be pre-assembled into non-load bearing panels and compressed for easy transport to the site, where they can be quickly expanded and adjusted for a precise fit every time.

How do the X-TENDA™ Telescopic Panels work?

The system works using three basic components: a C Stud, R Telescopic Stud and U Track. Because the R Telescopic Stud is slightly smaller in the web and flange, it can slide inside the standard C Stud, offering a precise range of adjustment.

X-TENDA™ 3600. The fastest way to build retrofit and infill framing.

Using BIM technology, the X-TENDA™ 3600 produces components ready to assemble. The telescopic panel studs are nested together, allowing them to extend up or down for horizontal and vertical adjustment. Simply extend the panel upwards and outwards on each side to perfectly fit the most uneven space, with doors and windows that remain perfectly square.

Telescopic panels can be pre-assembled and compressed for delivery. Pre-punched and fixing holes are self-locating, allowing the frames to be snapped together quickly and accurately. The frames are strong, lightweight and retractable, making them easy to manoeuvre and ideal for tight spaces and refurbishments.

X-TENDA™ Installation

The X-TENDA™ telescopic panels can be compressed for easy manoeuvrability, then moved into place, extended and installed for the perfect fit.

The most VERSATILE light steel roll-forming machine on the market

The versatility of the X-TENDA™ 3600 is hard to overstate. The machine handles everything from:

-

Standard stud and track framing components

-

Smart stud and track – our telescopic studs

-

Standard wall panels

-

Standard wall panel with deflection slot

-

Lattice trusses for roof and floor

-

Telescopic panel with deflection head slot

-

Multi-axis telescopic framing

-

Two-axis telescopic framing

-

Soffit telescopic framing

-

Kitset telescopic panels – flat packed (a Rollforming Services product)

-

Pre-assembled telescopic panels

-

Curved panels – also with telescopic

CHANGING THE SHAPE OF INTERIOR INSTALLATIONS, AND MORE!

Using telescopic panels manufactured by the X-TENDA™ 3600 can save you 50% or more on installation time for interior framing, and open up a world of possibilities for interior installers, including:

Easy assembly

Complete panels can be assembled in the factory or onsite in minutes - with 100% confidence panels will fit the space required.

Easy transportation

Panels are lightweight and can be compressed – so they can be transported in contractor vehicles and then carried up elevators or moved around tight spaces.

Greater productivity

A team of two installers can single-handedly assemble panels, move them into place, and frame up a wall in half the time or faster than traditional methods.

Perfect fit every time

Panels can extend outward and upward to fit any uneven or non-level space. It will even accommodate changes to the area after the pre-installation measure, such as an uneven floor.

True window and door spaces

Within the frame, doors and window sections remain perfectly square. Soffit panels can be screwed into the ceiling and pulled down to a laser line level with the floor below. Panels can also be multi-axis to allow for any angle.

Eliminate waste and disturbance

Because there is no need for measuring, snipping and cutting onsite, the X-TENDA™ 3600 panels mean less wastage and no excess framing to remove at the end of the job - saving on time, labour and materials.

The X-TENDA 3600TM is the Swiss Army Knife of light steel framing

- For general and interior contractors, this can mean simplified logistics since a single offsite supplier using one machine can fulfil multiple project requirements.

- For many larger contractors, the versatility of the X-TENDA™ 3600 makes it financially viable to invest in their own machine. As well as reducing both offsite and onsite related costs, it can create new revenue streams by utilising downtime to manufacture products for other contractors.

The Howick X-TENDATM 3600 – The most extendable machine in our range.

The panels manufactured by the X-TENDA™ 3600 can be used in a wide variety of situations to increase the efficiency of almost any construction project. What’s more, because the machine is so versatile, it can also be used to manufacture standard framing.

Here are some of the many applications this machine can be used to build:

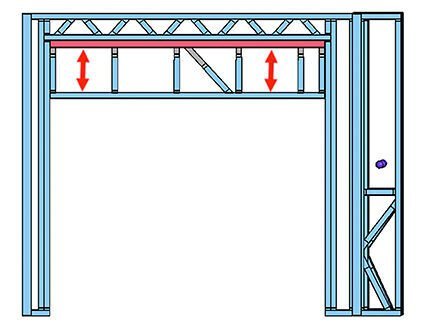

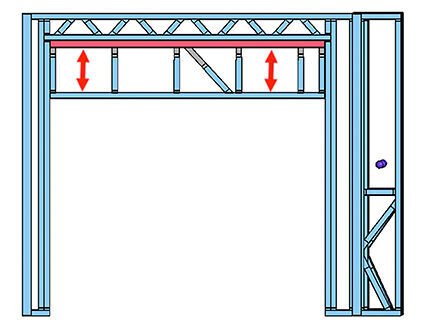

Soffit Panels

Soffit panels adjust up or down, across the frame to a set height. This makes accurate levelling up a breeze, as allowance can easily be made for non-level horizontal settings. Watch video.

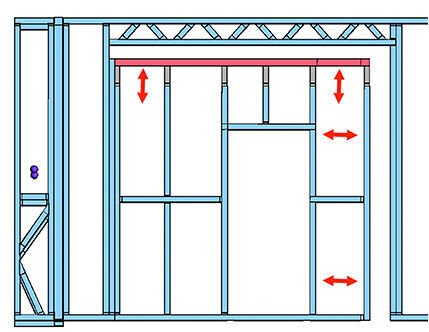

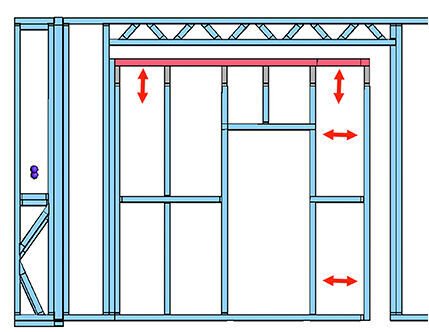

Two-Axis Expanding Panels

Two-axis expanding panels adjust upwards and outwards to fill the available opening. Within the frame itself, door and windows remain perfectly square. Watch video.

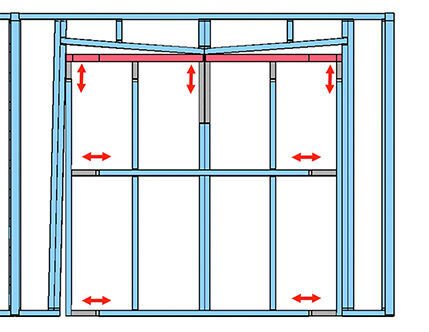

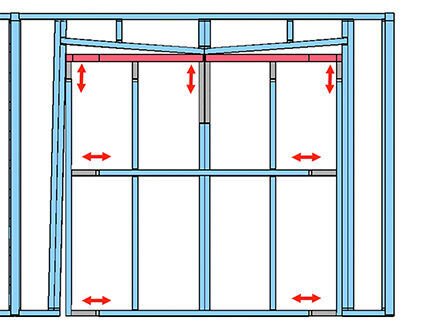

Multi-Axis Expanding Panels

Mult-axis expanding panels adjust upwards and outwards on both sides. This allows for different angles within the available opening. Watch video.

Standard Wall Panels, Roof & Floor Trusses

With a single machine, you can build standard, non-telescopic wall panels and lattice trusses for roof and floor. This means you can expand your production capability and extend your ROI from a single machine investment.

Bulkheads

Do away with the need to make onsite adjustments to accommodate for bulkhead spaces. Just line up the telescopic panels, drop to fit the area and line.

Raked or Vaulted Ceilings

Telescopic panels easily fit spaces which are demanding, for example, contemporary or period spaces with tricky, arbitrary designs and shapes.

Refurbishment

Often multi-storeyed refurbishment projects have limited workable space, limiting lift access, restricting workflows and schedules. Lightweight and retractable telescopic panel can squeeze into almost any area with ease.

Double T Installation

Framing out between pre-cast concrete double T flooring with our telescopic framing systems can now be done in a fraction of the time it takes using traditional methods.

Soffit Expanding Panels

Soffit Panels adjust up or down across the frame to a set height. This makes accurate levelling up a breeze as allowance can easily be made for non-level horizontal settings.

Two-Axis Expanding Panels

Two-Axis Expanding Panels adjust upwards and outwards to fill the available opening. Within the frame itself, door and windows remain perfectly square.

Multi-Axis Expanding Panels

Multi-Axis Expanding Panels adjust upwards and outwards on both sides. This allows for different angles within the available opening.

| X-TENDA™ 3600 | ||

| Gauge Range / Thickness | 0.8 - 1.2mm | 22 - 18gauge |

| Profile Width Options | 63.5 - 152.4mm | 2 1/2 - 6" |

| Profile Flange Height Options | 41.3m | 1.625" |

| Dimensions L X W X H | 4.4m x 0.75m x 1.4m | 14.4' x 2.5' x 4.3' |

| Weight | 2000kg | 4409lb |

| Drive Motor Power | 5.5kW | 7.4hp |

| Hydraulic Power | 4.0kW | 5.4hp |

| Hydraulic Tank | 40L | 10.6gal |

| Forming Stages | 14 | |

| Line Speed | 30m/min | 98'/min |

| Production Speed | Up to 800m/hr.* | Up to 2625'/hr* |

| Touch Screen | Panel PC (Windows 10) | |

| Machine Control | FRAMA Machine Control | |

| Machine Input Files | CSV | |

| Tooling | ||

| Component Marking | Dual Head Inkjet Printer | |

| Decoiler | ||

| 1.5T Decoiler | 3300lb Decoiler | |

| Dimensions L X W X H | 1.05m x 1.2m x 1.68m | 3.4' x 3.9' x 5.5' |

| Weight | 350kg | 770lb |

| Drive Motor | 2.2kW | 3hp |

| Jaws | 3 Jaw Self Centring | |

| Jaw Expansion | Hydraulic | |

| Jaw Expansion Range | 480mm - 520mm | 1' 7'' - 1' 8 1/2'' |

| Speed Control | Dancer Arm with Inclinometer | |

| Auto pause at coil end | ||

| Max Coil Weight | 1500kg | 3300lb |

| Max Coil Width | 200mm | 8'' |

| Mac Coil OD | 1500mm | 59'' |

| Nominal Bore | 508mm | 20'' |

| Safety | ||

|

* Production Speed will vary due to component complexity. Howick Ltd Reserve the right to update the machine specification without notice. |

||

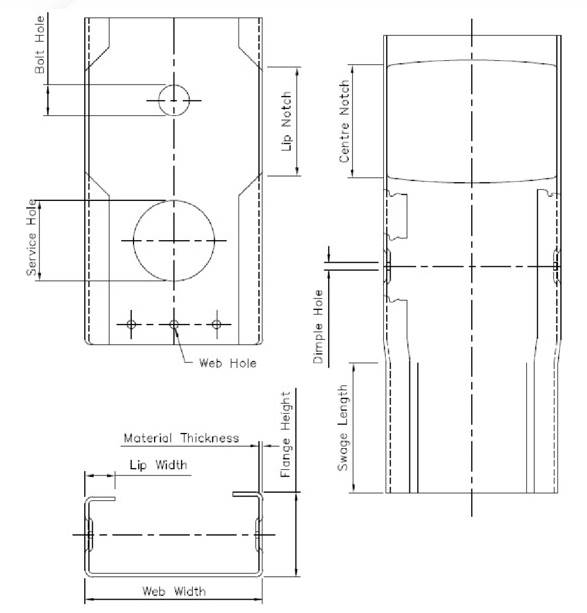

STANDARD METRIC SIZES

|

Section Size |

152.4mm | 92mm | 63.5mm |

| Web Width | 152.4mm | 92mm | 63.5mm |

| Flange Height | 41.3mm | 41.3mm | 41.3mm |

| Lip Width | 10mm | 10mm | 10mm |

| Service Hole *1 | 34.1mm | 34.1mm | 34.1mm |

| Bolt Hole *2 | 13mm | 13mm | 13mm |

| Web Hole *3 | 3.5mm | 3.5mm | 3.5mm |

| Dimple Hole *4 | 3.5mm | 3.5mm | 3.5mm |

| Nominal Strip Width | 253mm | 192mm | 192mm |

| Deflection Slot | 38.1mm x 5mm | 38.1mm x 5mm | 38.1mm x 5mm |

| Max Material Thickness | 0.55mm - 0.75mm 0.75mm - 0.95mm 0.95mm - 1.15mm |

0.55mm - 0.75mm 0.75mm - 0.95mm 0.95mm - 1.15mm |

0.55mm - 0.75mm 0.75mm - 0.95mm 0.95mm - 1.15mm |

STANDARD IMPERIAL SIZES

|

Section Size |

6'' | 3 5/8'' | 3 5/8'' |

| Web Width | 6' | 3 5/8'' | 3 5/8'' |

| Flange Height | 1 5/8" | 1 5/8'' | 1 5/8'' |

| Lip Width | 3/8" | 3/8' | 3/8'' |

| Service Hole *1 | 1 11/32'' | 1 11/32'' | 1 11/32'' |

| Bolt Hole *2 | 1/2'' | 1/2'' | 1/2'' |

| Web Hole *3 | 1/8'' | 1/8'' | 1/8'' |

| Dimple Hole *4 | 1/8'' | 1/8'' | 1/8'' |

| Nominal Strip Width | 9 61/64'' | 7 9/16'' | 7 9/16'' |

| Deflection Slot | 1 ½” x 5/64” | 1 ½” x 5/64” | 1 ½” x 5/64” |

| Max Material Thickness | 24 - 22 Gauge 22 - 20 Gauge 20 - 18 Gauge |

24 - 22 Gauge 22 - 20 Guage 20 - 18 Guage |

24 - 22 Gauge 22 - 20 Gauge 20 - 18 Gauge |