FRAMA™ 6800

Specialist Floor Joist System (13 Gauge / 2.5mm)

- Gauge Range

-

- Production Speed

-

- Dimensions L x W x H

-

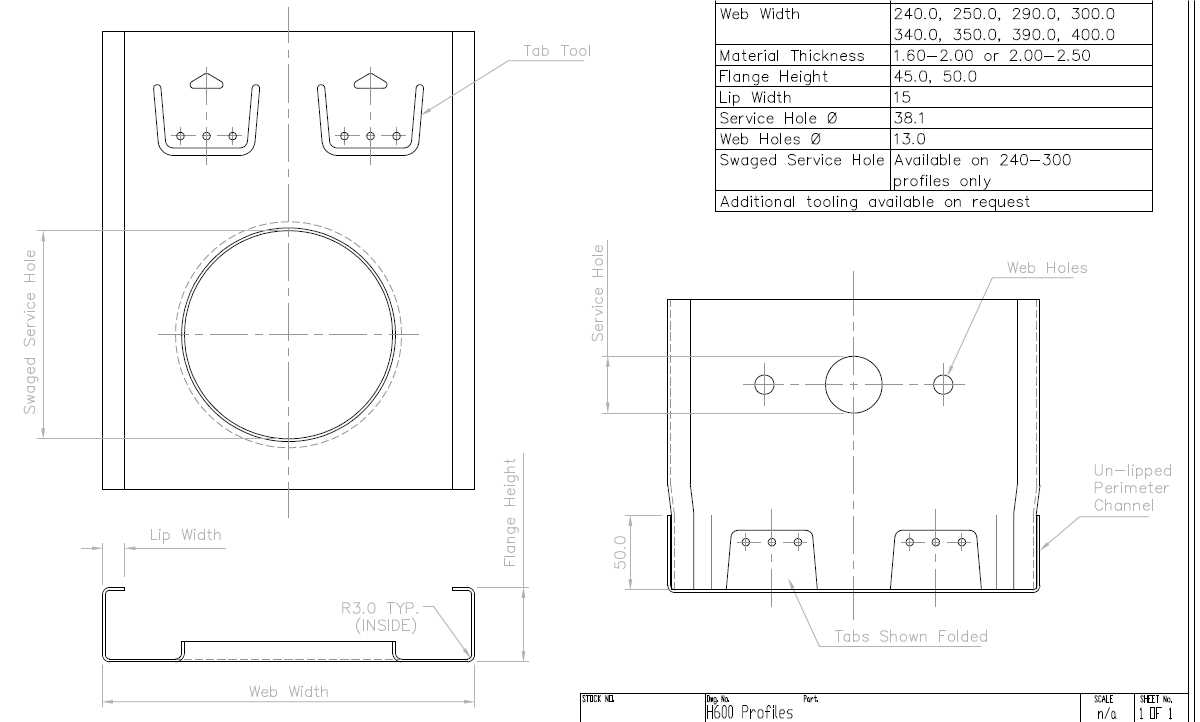

Looking for a dedicated floor joist cassette manufacturing option? The FRAMA™ 6800 will give you increased production capacity. You will also benefit from improved installation efficiency over standard lattice flooring systems. This machine features our unique swaged service hole to make ducting and plumbing easy. The Howick swage and tab design allows for smooth joints, so the floor lining is able to sit flush to the joists. The floor cassettes can be built as modular units or easily assembled piece by piece in existing structures.

It offers a gauge range of 2.0 to 2.5mm (14 to 13 gauge) and produces up to 600m/968ft of floor joists per hour.

| FRAMA™ 6800 | ||

| Dimensions L X W X H | 4.5m x 1.0m x 1.65m | 14.7' x 3.3' x 5.4' |

| Weight | 5000kg | 11023lb |

| Drive Motor Power | 11kW | 15hp |

| Hydraulic Power | 5.5kW | 7.5hp |

| Hydraulic Tank | 60L | 15.8gal |

| Hydraulic Cooler | Optional | |

| Forming Stages | 10 | |

| Line Speed | 20m/min | 65'/min |

| Production Speed | up to 600m/hr* | up to 1968'/hr* |

| Touch Screen | Panel PC (Windows 10) | |

| Machine Control | FRAMA Machine Control | |

| Machine Input Files | CSV | |

| Tooling | 7 Standard Tools | |

| Swaged Service Hole, Service Hole, Bolt Hole, Tab, Lip Roller, Swage, Crimping Cut-off | ||

| Component Marking | Dual Head Inkjet Printer | |

| Decoiler | ||

| 3.0T Decoiler | 6,600lb Decoiler | |

| Dimensions L X W X H | 1.35m x 1.0m x 1.45m | 4.4' x 3.3' x 4.7' |

| Weight | 700kg | 1550lb |

| Drive Motor | 4.0kW | 5.4hp |

| Jaws | 3 Jaw Self Centring | |

| Jaw Expansion | Hydraulic | |

| Jaw Expansion Range | 480mm - 520mm | 1' 7'' - 1' 8 1/2'' |

| Speed Control | Dancer Arm with Inclinometer | |

| Auto Pause at Coil End | ||

| Max Coil Weight | 3000kg | 6600lb |

| Mac Coil Width | 400mm | 1' 3 3/4'' |

| Mac Coil OD | 1500mm | 4' 11'' |

| Nominal Bore | 508mm | 1' 8'' |

| Safety | CE, UL, Cat 3 Compliant | |

| Guarding | Fully Guarded Chains & Electrical Controls | |

| *Production Speed will vary due to component complexity. Howick Ltd Reserve the right to update the machine specification without notice. | ||

STANDARD METRIC SIZES

|

Section Size |

200mm | 250mm | 300mm |

| Web Width | 200mm | 250mm | 300mm |

| Flange Height | 50mm | 50mm | 50mm |

| Lip Width | 15mm | 15mm | 15mm |

| Service Hole *1 | 34.1mm | 34.1mm | 34.1mm |

| Bolt Hole *2 | 13mm | 13mm | 13mm |

| Swaged Service Hole *3 | 80mm | 140mm | 140mm |

| Tab *4 | Single Tab | Double Tab | Double Tab |

| Nominal Strip Width | 310mm | 360mm | 406mm |

| Max Material Thickness | 2.50mm | 2.50mm | 2.50mm |

STANDARD IMPERIAL SIZES

|

Section Size |

8'' | 10'' | 12'' |

| Web Width | 8" | 10'' | 12'' |

| Flange Height | 2" | 2" | 2" |

| Lip Width | 19/32" | 19/32" | 19/32" |

| Service Hole *1 | 1 11/32'' | 1 11/32'' | 1 11/32'' |

| Bolt Hole *2 | 1/2'' | 1/2'' | 1/2'' |

| Swaged Service Hole *3 | 3'' | 5 1/2'' | 5 1/2'' |

| Tab *4 | Single Tab | Double Tab | Double Tab |

| Nominal Strip Width | 5 19/32'' | 14 3/8" | 6 13/16'' |

| Max Material Thickness | 12 Gauge | 12 Gauge | 12 Gauge |

*1 & 2 Combines Service and Bolt Hole. Custom Service Holes and Slots available on request

*3 Custom Swaged Service Hole

*4 Smaller sections have a single tab while larger sections utilise a double tab configuration