STEEL HORIZONS | BOSTON Speaker Series 9 - Generative workflows for industrialisation of construction with Jim Stoddart.

⏱️ 5 min read

Step into the future of industrialised construction with our exclusive STEEL HORIZONS | BOSTON speaker series. In each post, we spotlight one speaker from our STEEL HORIZONS | BOSTON event and share their insights about the future of construction.

Next up is Jim Stoddart. Jim is a core member of The Living, an Autodesk studio, as well as a research scientist in the AEC Industry Futures group at Autodesk, whose work explores how new design, construction and material technologies will lead to a better built environment. In his fascinating talk, Jim discusses how generative design is enabling the industrialisation of construction.

Jim Stoddart has built his career on looking forward to what is possible in the architecture, engineering and construction (AEC) industries. He has published peer-reviewed papers, won multiple industry awards for his designs, and holds patents for key generative design applications.

In his STEEL HORIZONS | BOSTON presentation he shares stories of his collaborations with industry leaders, which demonstrate the huge potential of machine learning and generative technology design in the AEC industries.

Introducing Autodesk Industry Futures

Industry Futures sits between core research, where the tech that will power the future of the AEC industries is developed, and the industry, where innovative companies continue to do great things.

The idea is that Jim and his team take tech developed via their research and test it in the real world, with willing partners on real projects. Through this experimentation they can push the envelope of what is possible with technology in AEC so that eventually customers can use this new technology in their own projects.

The power of generative design

One of the most promising areas Jim is exploring is generative design and its ability to manage complexity throughout the design, engineering and construction phases of a build:

“It works because it’s a collaboration between machines and humans … It enables us to do things like rapidly explore options and correlate huge amounts of data.”

These generative design systems can help us create, evaluate and evolve better versions of space planning and work within the constraints of a project, evaluate what is good and bad in terms of design, and even incorporate complex factors like people’s preferences.

The Industry Futures team put this technology to the test to design a floor plan for Autodesk’s own office in the Toronto MaRS Discovery District Innovation Hub. First, they input the types of things that the building’s users cared about, such as access to natural light, distraction levels, and proximity to the tools and teams they needed. Next, they let the system scrub through possibilities:

“The system churns through options, tests them, then finds the best version from every generation. Then cross breeds them and makes children. The idea is it’s a loose replication of natural selection.”

Jim explains that 90% of the results are trash. But the system helps find the gems, then the team pulls them out and assesses whether they achieve design goals. The result is an incredible office that is both beautiful and functional.

Navigating complex, interconnected problems

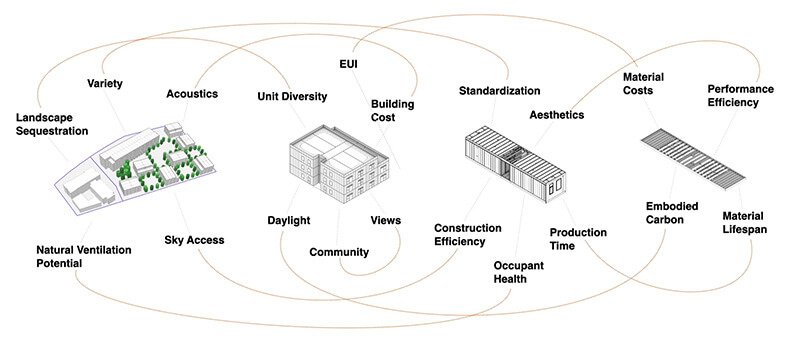

The model required to manage complex construction projects from end-to-end must focus on solving a series of interconnected problems:

“How do we start to set up a system where we make connections? How can computational and generation workflows solve problems by having a holistic approach to design?”

The solution Jim says, is not to create a giant model. But to build a data layer under all models - graphs that represent all connectivities and relationships embedded in this model. Every element knows how it is related to the whole and all other elements.”

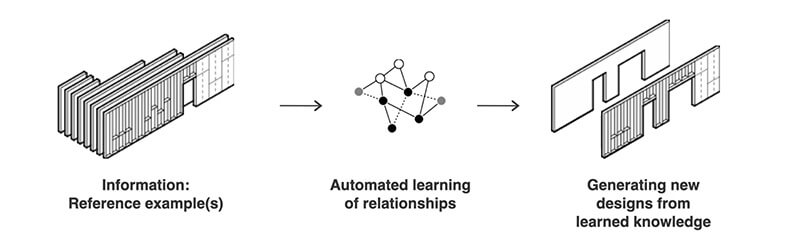

This was a key part of making the process simpler so that more stakeholders could engage with the systems. And by using what systems already know, Industry Futures was able to help a modular construction company automatically generate optimised designs without inputting rules - just their catalogue of buildings. This model connects to other prototypes the team has developed, including KRATOS, a structural optimisation software:

“This optimises the design of a structure from the geometry before, based on gravity loads, wind loads, seismic loads and sheer forces and optimises to reduce weight, embodied carbon and cost, all the while maintaining structural targets.”

The output is a building information model that enables us to easily get the design out of the computer and onto the site.

A new era of automation

With these advancements we are now entering a new era of possibility for the automation of construction. We are moving past simple parametric modelling, towards generative design and generative AI that can understand intent in models without explicit programming.

In other words, AI can start to find things humans might be missing, that are locked in people’s heads, and even learn from past experience:

“The output is construction-ready design, auto-completed designs, construction-ready detailing and assembly sequences. We have an LOD [level of detail] model but we also know how to put it together, tool requirements, multi-trades and material handling.”

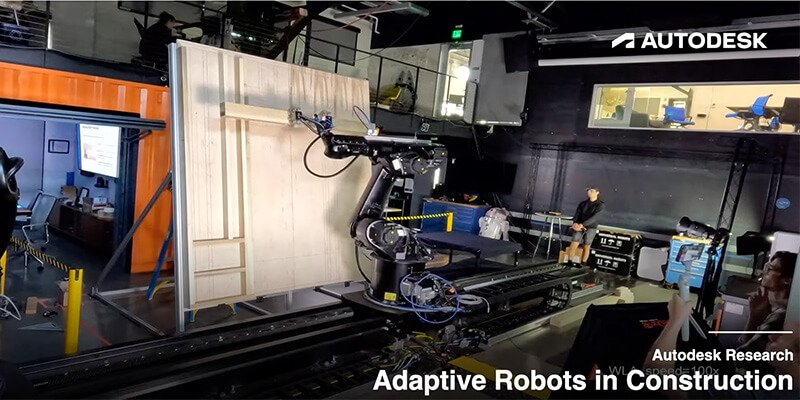

We are now at the point where this technology allows us to start automating phases of construction using adaptive robots (and the Industry Futures team are already experimenting with this).

“We generalise info assembly cells, give it a bill of materials and a final drawing and the system scans pieces, then figures out how to put them together and how to pick them up.”

This points to a future where if we have enough data about how things come together in a digital model, we can start to design new construction systems that specifically enable use of generative systems and fully automated construction.”

“The future is bright here, the technology is advancing fast and it's enabling this new possibility of how we put things together.”