Cold formed steel: The future of construction – benefits, applications & innovations

⏱️ 6 min read

In a rapidly evolving construction industry, cold formed steel (CFS) is re-defining what’s possible. From its superior strength-to-weight ratio to its precision-engineered performance, CFS is fast becoming the material of choice for forward-thinking builders, developers, and engineers.

At Howick, we have been at the forefront of roll-forming technology for almost 50 years, helping the construction sector harness the full potential of cold formed steel. Whether you're designing modular buildings, large-span structures, or seismic-resistant frameworks, CFS—paired with Howick’s advanced automation—offers a smarter, faster, and more sustainable way to build.

What is cold formed steel?

Cold formed steel – also known as light gauge steel - is manufactured by shaping thin-gauge steel sheets at room temperature using precision roll-forming technology. Unlike hot-rolled steel, which is formed at high temperatures, CFS maintains tight tolerances and higher yield strength due to the work-hardening effect of the cold-forming process.

This results in lightweight yet structurally robust components that resist warping, shrinking, and corrosion—key advantages in modern construction.

No time to read? Here are the key take-aways

Cold formed steel (CFS) benefits: Offers superior strength-to-weight ratio, precise manufacturing, sustainability, resistance to fire, pests, seismic events, and significantly reduces waste.

Precision and efficiency: Automated roll-forming technology, such as Howick's FRAMA™ machines, delivers high accuracy, minimising onsite labour and installation time by up to 50%.

Environmental benefits: CFS is highly sustainable, 100% recyclable, has minimal waste, and contributes positively to circular economy practices.

Innovative applications: Widely used in modular construction, large-span structures, seismic retrofits, and prefabricated solutions, demonstrating versatility across construction scenarios.

Cold formed vs hot rolled steel: CFS is produced at room temperature providing superior dimensional accuracy, smoother finish, and sustainability advantages, whereas hot-rolled steel is energy-intensive, requires additional coatings, and is less precise.

Cold formed steel vs timber - CFS offers many benefits over building with timber and concrete. Check out our article to find out how construction with cold formed steel compares with timber.

Table of Contents

The BENEFITS of cold formed steel in construction

1. Strength, durability & seismic performance

CFS boasts an exceptional strength-to-weight ratio, enabling buildings to withstand heavy loads while remaining lightweight. In seismic-prone regions, cold formed steel’s inherent flexibility and resilience make it a superior choice over traditional materials like wood or concrete.

Case in point: In New Zealand’s Victoria Lane Apartments project, Howick’s X-TENDA™ 3600 roll-formed telescopic framing panels enabled rapid, precision-fit installations while improving seismic resilience.

2. Faster, more efficient construction

Cold formed steel is manufactured with pinpoint accuracy using automated roll-forming machines like the Howick FRAMA™ 7600. This reduces rework, speeds up installation, and minimises waste.

As a demonstration of this, a Howick customer, M3 Components (M3C) - a Californian company revolutionising healthcare construction with offsite manufacturing - working with S+B James Construction, demonstrated that panelised, offsite roll-formed steel construction saves significant time and money.

3. Design flexibility & BIM integration

Cold formed steel seamlessly integrates with Building Information Modelling (BIM) and computational design software, allowing for precision fabrication of complex architectural structures.

With Howick’s open-source machine control systems, manufacturers work with leading design platforms such as Autodesk Revit, Strucsoft, Tekla, and Vertex, ensuring seamless workflows from design to fabrication.

4. Cost-effectiveness & minimal waste

Cold formed steel is more than just efficient—it is economical. Prefabricated CFS components arrive onsite ready to assemble, reducing labour costs and material waste. Unlike timber, CFS does not require time to dry out, and there is no wastage due to warping or pest damage.

5. Sustainability & recyclability

Cold formed steel is one of the most sustainable building materials available. Made from up to 25% recycled content, CFS is 100% recyclable at the end of its life, contributing to circular economy principles.

In contrast to concrete and timber, which generate significant waste, CFS offcuts are minimal and fully reusable.

6. Fire, mould & pest resistance

Unlike wood, CFS does not burn, warp, rot, or attract termites. In fire-prone regions, its non-combustible nature provides an added layer of safety and longevity.

Cold formed steel vs. hot rolled steel

|

Feature |

Cold formed steel |

Hot rolled steel |

|

Manufacturing process |

Formed at room temperature |

|

|

Precision & consistency |

High dimensional accuracy |

Prone to warping & shrinkage |

|

Strength-to-weight ratio |

Superior |

Requires more material for the same load |

|

Surface finish |

Smooth, clean edges |

Rougher texture, oxidised surface |

|

Sustainability |

100% recyclable, low waste |

More energy-intensive, requires additional coatings |

For applications requiring ultra-precise, lightweight, and cost-effective solutions—such as modular construction, infill framing, or prefabricated walls—cold formed steel is the clear winner.

Sources:

Innovations in cold formed steel manufacturing

Howick has been pioneering automated roll-forming for decades, and our latest innovations continue to transform the way the industry builds:

-

XTENDA™ 3600 Telescopic Framing System – Adjustable steel framing panels that expand onsite, cutting installation times by 50%.

-

FRAMA™ Roll-forming Machines – Precision-engineered steel framing systems capable of producing load-bearing frames, joists, and trusses with millimetre accuracy.

-

Mobile factory solutions – Self-contained, transportable roll-forming units, used by the U.S. Navy Construction Battalion to build infrastructure in remote and disaster-stricken areas.

Cold formed steel in action: real-world applications

1. Modular & prefabricated construction

Cold formed steel is widely used in modular housing, student accommodations, and hotels, where speed, precision, and quality control are paramount.

Example: Broadmeadows project in Australia – Howick-powered modular construction slashed framing installation time from weeks to days.

2. Complex computational design & fabrication

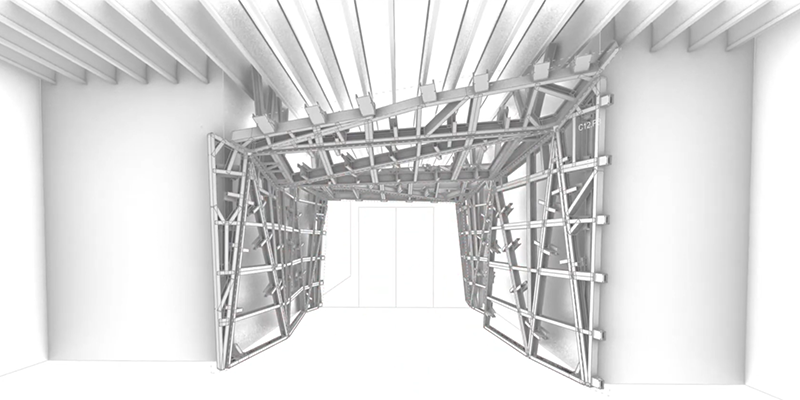

Computational design and precision manufacturing combine using CFS to enable complex architecture to be achievable with speed, accuracy and minimal re-work.

Example: The Portal in California – a sculptural steel-framed medical facility entrance designed with Howick roll-forming precision.

3. Large-span & multi-storey buildings

CFS enables the construction of expansive, clear span spaces such as warehouses, data centres, and industrial facilities.

Example: The Tokoroa Industrial Portal Building, at 44m long and 25m wide, where materials were trucked to the site, and the CFS portal installation was completed in just over 4 hours with a crane and access lifting platform.

4. Retrofitting & seismic upgrades

CFS is ideal for reinforcing older buildings with lightweight yet high-strength steel framing solutions.

Example: Victoria Lane Apartments in New Zealand – Seismically robust, telescopic steel framing

Why choose Howick for cold formed steel solutions?

“The construction industry has massive potential to leverage technology for smarter, more efficient builds. Cold formed steel, paired with the right automation, is proving to be the future of construction.”

– Nick Coubray, CEO, Howick Ltd

With nearly five decades of expertise, Howick’s precision roll-forming technology is trusted by contractors, modular builders, and construction innovators worldwide.

Industry-leading accuracy – Precision down to 1/64th of an inch or 0.5mm.

Seamless software integration – Works with all major BIM and CAD platforms.

No hidden fees – No toll-roll costs or software licensing restrictions.

Proven performance in the field – Backed by real-world case studies.

Discover how Howick can transform your projects. Get in touch today to learn more about our cold formed steel solutions.

Pass this knowledge along - share this article today.

April 2025 #Features