STEEL HORIZONS | BOSTON Speaker Series 3 - Brandon Ionata on the convergence of design and fabrication

Step into the future of industrialized construction with our exclusive STEEL HORIZONS | BOSTON speaker series, where we spotlight one of our expert speakers and share their insights about what is coming in the world of construction.

This edition, it is Brandon Ionata, Solution Line Senior Director at StrucSoft | Graitec Group. StrucSoft is a company that is looking to revolutionize construction through software. Brandon's insights provide a glimpse into how we can use tools like Revit to bridge the gap between design and manufacturing.

Reimagining the role of BIM in construction

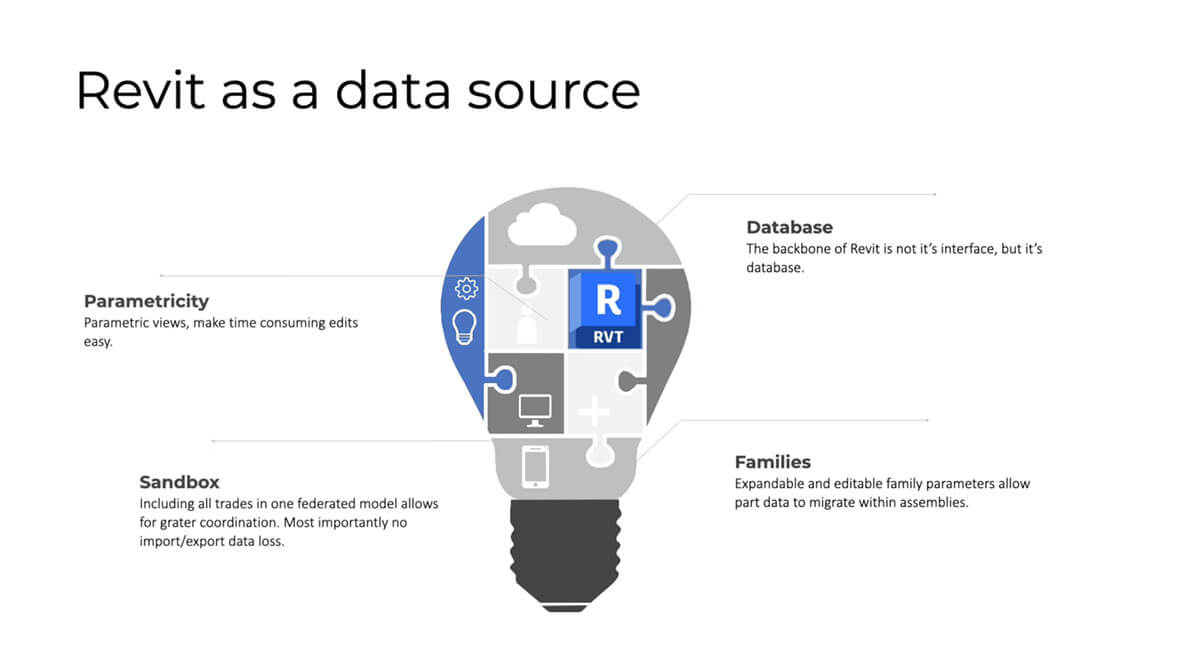

While traditionally, most of us look at BIM and tools like Autodesk's Revit as a design tool, Brandon argues it is much more than that.

"I really want to talk about Revit as a data source and a fabrication tool for this industry.”

Revit's power is not its interface but its database and capacity to transform your workflow. It can be a sandbox for greater trade coordination and group related data in "families" to migrate within assemblies.

"All this information is in the Revit model, and as programmers, we can build software to call on each bit of that data and manipulate it to produce very precise machine code to automate [construction] manufacturing through technology like Howick's."

Crucial for success in industrialized construction

Precision in data and modeling is crucial for successful industrialized construction. Brandon says that by using Revit as a single source of truth, you can maintain that precision and avoid errors and inefficiencies downstream.

Using the ‘design to modeling to fabrication’ workflow, Brandon demonstrates how tapping into Revit’s full potential can enhance precision and efficiency in production.

Take the source data

You start with the architect's Revit model, so no data is lost.

Build a structural model

Building on top, you layer in the precision and coordinate construction.

Develop a fabrication/framing model

Next, you develop the fabrication model from framing to fully enclosed wall panels with insulation, vapor barriers and MEPs. Rather than exporting data, Brandon advocates using the precision of Revit as a single source of truth to gain better visibility over MEPs, do clash detection, and reduce manufacturing errors and machine time.

Shop documentation

With all your data in Revit, you can now automatically create a range of shop documentation from traditional 2D shop drawings to laser layout tables, QR tagging and RFIDs.

Fabrication

Successful companies are planning what to fabricate based on their construction plan. New tools allow this data to be extracted from Revit and presented in a user-friendly cloud environment for production planning.

The key to all of this lies in the ability to maintain, expand and manipulate precise data from a single source of truth.

Bridging the gap between design and manufacturing

Where things get interesting is when the data hits the shop floor, says Brandon. The question has always been whether the shop team need access to the Revit model.

Things like glue lines do not belong in the Revit model and slow it down, yet they are essential to the shop. This is where software solutions like those StrucSoft create can help. They extract the data from Revit and provide a user-friendly cloud environment for production planning.

StrucSoft also has solutions that allow operation teams to view, check and edit the CNC code for manufacturing and production without affecting the integrity of the underlying Revit model.

The benefits by the numbers

Brandon says businesses are self-reporting significant efficiencies by adopting Revit as a data platform for fabrication and enhancing it with customized software solutions. These efficiencies include:

20% faster design-to-production

Compared to solutions requiring third parties, design-to-production is significantly reduced by keeping the framing data in Revit.

42% faster fabricated drawings

3D model parametricity and drafting automation speed up 2D fabricated drawings by reducing errors and change orders.

10% productivity savings on project delivery

Managing panel stacking, roll orders, and production sequencing in 3D collaborative environments is significantly more efficient than conventional spreadsheets.

90% reduction of scrapped panels

Compared to manual check and edit processes in older systems, CNC output control and editing in 3D dramatically reduces errors.

Was this article insightful? Share it

February 2024 #Features