SMART BUILD SPOTLIGHT - Lark Builders bring modern construction to the humble shed

⏱️ 5 min read

Welcome to the second in the SMART BUILD SPOTLIGHT series, where we profile trailblazing businesses using converging technologies and smart building processes to raise the standard of our industry.

Every company we showcase here is pushing the boundaries of modern construction with their own unique approach and achieving outstanding results.

We featured Wolf Partners in our previous series, a relatively young company in Tampa, Florida, with their fully vertically integrated development, architecture, fabrication and building construction model. We now look at Lark Builders in Vidalia, Georgia, a highly successful three-generation family business with a single-minded focus on building superior sheds.

While there is obvious contrast, these two companies have more in common than meets the eye. What both businesses share is a mindset of constant improvement, a track record of success and a commitment to automation and cold formed steel roll-forming technology.

Watch the SMART BUILD SPOTLIGHT interview video OR read the article below to get the full story.

Family business with a backbone of steel

Sitting behind a desk filled with orders and in front of a large family photo, Bob Moore is right at home.

As the President of Lark Builders, Bob grew up in the business his father started, and has run it ever since his father passed away and his mother retired.

Today, Lark Builders is a thriving three-generation business with a large operation based in Georgia, which employs Bob’s wife and three sons. The company is a leader in manufacturing sheds, primarily for the Florida market.

“We build the best, and we stand behind it.”

“We don't use a lot of gimmicks or make a lot of noise, but we build a good product.”

Key to their success has been a commitment to improving the product and an early decision to invest in roll-forming steel technology and automation practices. In 1998, they were already building steel frames out of electrical conduit braced together with brass, but they wanted to replace that method with a more scalable option when they went to the Metalcon show that year.

“[We] saw the equipment that Howick makes and we were really impressed with it.”

At the time, steel only cost 25 cents per pound and switching from wood was a no-brainer for Lark Builders. Wood was labour-intensive and produced more waste; where steel was consistent and produced a better product that their customers loved.

Tariffs on imported steel in the 2000s slowed their transition towards steel, but that changed when Bob’s eldest son, Robert, knocked on his office door in 2016.

The driving force behind better ways of building

“(Robert) is instrumental in the business…he's been a big part of us getting really into the steel.”

With his mix of digital and mechanical skills and understanding of production, Robert works closely with Bob, providing direction on new technologies and modern construction methods. Robert saw the untapped potential of steel and was the key influence behind the business’s pivot to exclusively using cold formed steel framing.

Together, they looked at the numbers again and realised that roll-formed steel construction was still the best option for both the business and customers – even with higher steel prices.

“We had costed it before, but we probably didn’t put as much emphasis on the labour as we should have….It was a lot less labour intensive and the product was a lot better.”

Uncovering the true cost saving of steel framing

Building with steel has many advantages over wood, but two qualities made it a clear winner for Lark Builders’ operation: speed of construction and reduced waste.

Using Howick machines, Lark Builders can plan out manufacturing with precision. Every component can be produced in sequence with pinpoint-accurate measurements for pre-punched holes, fixings, and tracks. This capability has transformed how they assemble prefabricated panels.

“To get a wood wall out, it took about nineteen people to get it to the point you could put it on a floor to build a shed. With steel, you’ve got three people on the machine and about eight people assembling. It’s a lot less labour intensive.”

Steel also produces next to no waste and is 100% recyclable. When they were building with wood, Lark Builders were pulling out about 20% of the wood as off-cuts or faults. This wood then needed to be transported and disposed of – all of which cost more money. Those costs disappeared when they started working exclusively with steel.

“You can take a steel building – say one that is 12 ft by 24 ft – and in your hand hold the steel you wasted running out that product. And we actually get paid some for the scrap steel.”

Contrary to some opinions, steel can be the more environmentally friendly choice. While timber may be organic, the processes of milling, treating, transporting, and disposing of it all contribute to energy consumption and pollution. In contrast, steel’s longer lifespan and recyclability make it a more sustainable option.

Sheds, steel and the Sunshine State

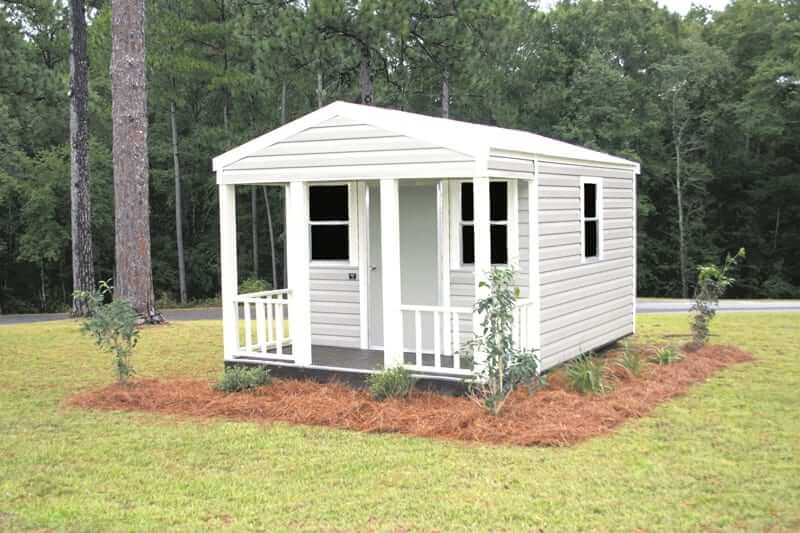

While Lark Builders has looked at other types of buildings, like tiny homes, they have remained focused on manufacturing high quality sheds. It is a sweet spot for the business where there are good margins and they have full quality control over the product.

|

|

By concentrating on being the best in one category, they have established a strong position in Florida, which is now their largest market.

With Florida’s large population and vulnerability to extreme weather events, its construction industry is highly regulated. Lark Builders is one of the few companies with the experience, expertise and operational scale to successfully service this market.

Working with steel framing also gives them a clear advantage in Florida, where extra hardware is required to secure wooden framing for wind speeds. When Lark Builders built with wood, they would replace up to sixty studs a day after they completed a panel due to splits and cracks.

“Steel is lighter and easier to work with, and you don’t have to tug around a big old heavy nail gun.”

Customers also prefer steel, so long as the price is competitive with wood, says Bob.

“They like the characteristics of the steel better. You get a straighter wall, straighter floors. The consistency and the quality, it is a lot better.”

Levelling up operations with Howick machines

To achieve this transition to steel framing, the business has continued to partner with Howick and invest in our roll-forming technology. Like Lark Builders, Howick is a multi-generational family business committed to continuous product improvement and delivering exceptional service.

It is a partnership that has spanned over two decades, and from Bob’s point of view, it has been highly successful at every stage of their journey.

“It’s been a real positive experience. It’s good dependable equipment,”

“The technology that y'all put into them has been phenomenal.”

Framing up for future success

Having firmly established their market share in Florida and with a well-oiled operation in Georgia, Lark Builders is strategically venturing into new product lines that capitalise on their core competencies, signalling their adaptability and potential for future growth.

“We fabricate all our materials. We’re somewhat vertically integrated from the standpoint of doors, sidings and stuff like that.”

In particular, garage doors show real potential. There is already significant demand from other construction companies without advertising or promoting the product. Currently, the company is focused on servicing its own needs while optimising the process, but it clearly sees a promising opportunity ahead.

“We hopefully will have some organic growth, and the boys will be able to grow the business.”

Based on their successful track record to date, we are sure the future for Lark Builders will continue on its trajectory: one of constant improvement and impressive growth.

Was this article insightful? Share it

August 2024 #Features