How Lark Builders turn sheds into a high-tech success

⏱️ 3 min read

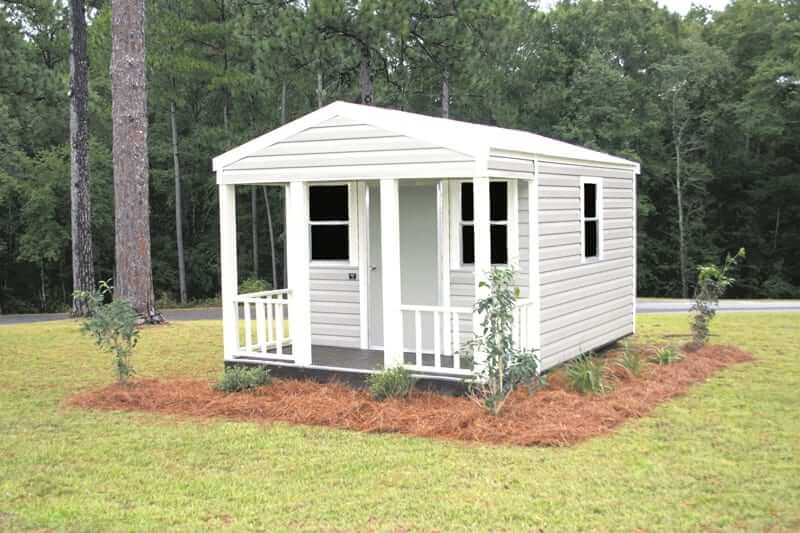

Imagine transforming a humble family shed building business into a high-tech, three-generation powerhouse. That’s exactly what Bob Moore and son Robert, of Lark Builders, did. And now, in SMART BUILD SPOTLIGHT, we're giving you an insight into how they did it...

.... from switching traditional timber out for cold-formed steel and building automation...

... to growing a small family operation in Georgia into one of the biggest names in sheds, primarily for the Florida market.

The best part?

You can watch the full SMART BUILD SPOTLIGHT video interview with Lark Builders below.

Here’s the Lark Builders story, in 5 minutes or less:

✔️ Building a Backbone of Steel

✔️ The Secret Weapon: Automation

✔️ What Changed? A Whole Lot

✔️ Building for the Future

Building a Backbone of Steel

Lark Builders was started back in 1967 in Georgia by Bob’s father. After his father sadly passed away, Bob’s mother continued the business until Bob returned from college.

Since then, Bob and his family have continued to build the business into what it is today: a leader in manufacturing high-quality, durable sheds that stand up to Florida’s challenging weather conditions.

But they didn’t get there by sticking to the old ways.

From early on, they saw benefits in switching from timber to light steel construction, initially building steel frames out of electrical conduit braced together with brass.

The rationale for steel was a no brainer.

At the time, steel was low cost. Wood was labour-intensive and wasteful, while steel was more efficient, consistent, stronger and better suited to the tough Florida climate.

There were environmental benefits too. The processes of milling, treating, transporting, and disposing of the timber waste all contributed to energy consumption and landfill.

In contrast, steel has a long lifespan and creates virtually no waste. And it’s 100% recyclable!

Simply put, steel produced a better product that their customers loved. “We build the best, and we stand behind it,” Bob says.

The Secret Weapon: Howick Roll-Forming Automation Technology

At the heart of Lark Builders total transformation to steel was one thing: Automation.

In 1998, a trip to the Metalcon show fuelled an early decision to invest in roll-forming steel technology.

“[We] saw the equipment that Howick makes, and we were really impressed with it.” Bob explains.

However, tariffs on imported steel in the 2000s stunted their transition towards steel.

That changed when Bob’s eldest son, Robert, knocked on his office door in 2016. With a mix of digital and mechanical skills plus an understanding of modern production, he could see the potential for full automation.

“We had costed it before but probably didn’t put enough emphasis on the labour. [Steel] was a lot less labour intensive, and the product was a lot better.”

Using Howick machines, they could execute with pinpoint precision. Every component could be automatically produced in sequence with pre-punched holes, fixings, and tracks.

Together, they made the full switch to exclusively building with cold-formed steel framing using Howick’s cutting-edge roll-forming technology.

What Changed? A Whole Lot

Speed and efficiency were the biggest change. And the product was superior.

“To get a wood wall out, it took about nineteen people to get it to the point you could put it on a floor to build a shed. With steel, you’ve got three people on the machine and about eight people assembling. It’s a lot less labour intensive.”

|

|

Prefabricating panels with Howick technology has been transformational:

- Less labour, more precision: What took 19 people handling wooden walls, now takes 11 people and the Howick machine.

- Next to no waste: With wood, they had 20% waste going into landfill. With steel? Bob says he can fit the waste in his hand.

- Stronger and more reliable: Steel is better suited for Florida’s extreme weather, and customers prefer the consistent quality.

Working with cold formed steel also gives Lark Builders a clear advantage in Florida, where extra hardware is often required to secure wooden framing for wind speeds.

When Lark Builders built with wood, they would replace up to sixty studs a day after they completed a panel due to splits and cracks.

“Steel is lighter and easier to work with,” Bob says, “and you don’t have to tug around a big old heavy nail gun.”

Want to learn how building with steel could transform your business? Check out all the benefits of cold formed steel.

Building for the Future

“We fabricate all our materials. We’re somewhat vertically integrated from the standpoint of doors, sidings and stuff like that.”

In particular, garage doors show real potential. They already have significant demand from other construction companies despite not advertising.

“We hopefully will have some organic growth, and the boys will be able to grow the business.”

Their story is one of constant improvement, a trait they share with us at Howick. After two decades of partnership, Bob says it’s been a real positive experience.

“It’s good, dependable equipment. The technology that y'all put into [machines] has been phenomenal.”

Curious about how Howick technology can take your business to the next level?

Download our Machine Buyer Guide – it’s got everything you need to know about transforming your building approach with precision steel roll-forming technology.

Watch the full interview with Bob Moore, see the machines in action, and learn how Lark Builders is framing up for future success.

If you are ready to enjoy the transformational benefits of light steel automation with Howick technology, talk to us today.

Was this article insightful? Share it

November 2024 #Features