Engineering success: The secret to growth for Hyspecs & Howick

⏱️ 3 min read

A decade ago, Hyspecs saw an opportunity to work with Howick, potentially improving efficiencies and build times for our machines. They approached us and started a conversation. We quickly found that we had the same shared obsession with innovation and attention to detail. Plus, Hyspecs demonstrated the expertise needed to help Howick continue in its evolution delivering world-leading, NZ-built machines.

Fast forward to today and we have built an enduring and successful partnership, as two homegrown, 100% Kiwi businesses in a field dominated by international players.

We have seen Hyspecs evolve into a leader in hydraulic and electrohydraulic systems. They have expanded into Australia, further grown their manifold manufacturing company, and diversified into electronics and industrial automation. All this, thousands of miles away from most of their suppliers.

We sat down with Hyspecs’ CEO, Richard Krebs, to find out how they overcame NZ’s isolation to rise to the top of a challenging industry – and what we can learn from their success.

How Hyspecs found their niche in the industry

Back in 1972 Hyspecs’ founder Wynne Cranston saw a need for a hydraulic company that engineered the best possible solution for the client without being restricted to a specific brand. Richard says that engineering focus continues to this day:

“We have intensive technical training for our sales and service people. This allows us to give the client more than a box in box out model.”

The approach is clearly working. Hyspecs has New Zealand’s largest hydraulic stock holding, manufacture, assembly and service centres in Auckland, Christchurch and Australia and a sister company, Hytech.

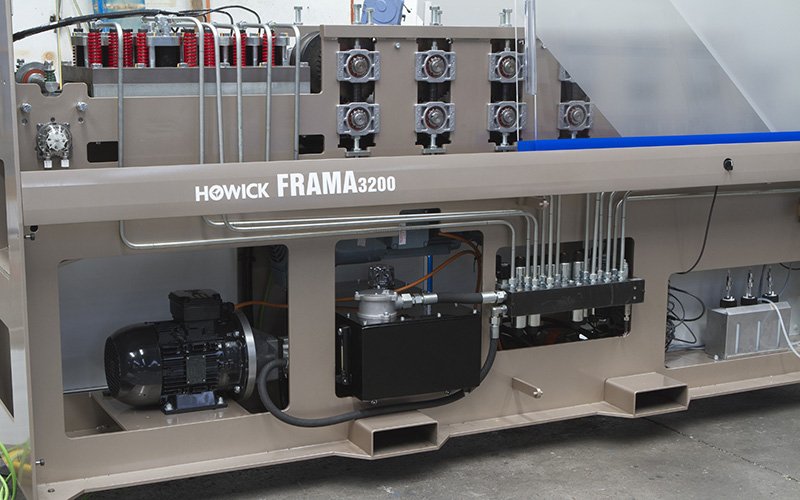

Wayne Rowe, General Manager at Howick, says Hyspecs has been a valuable supplier and supporter for almost a decade - supplying motors, pumps, valves and manifolds ever since Howick started building the first FRAMATM roll-forming machines:

“They have always been keen collaborators and work closely with our teams on engineering and innovation to help solve some of the technical challenges.”

“Their dedicated support and exemplary customer service has been a key stand out. They’re just so easy to work with and they are always happy to work alongside us to find the best solutions to our design challenges.”

The (not-so-secret) secret to success

Richard explains that his company’s secret to success is not much of a secret:

“Our emphasis is and has always been a total focus on the customer’s needs. We do this through thorough engineering of their systems to develop the best fit for the application.”

“We see our customers as long-term partners. Their success translates to our success. This makes a virtuous cycle where the normal ‘them and us’ barriers are replaced by just “us”.”

Solving their customers' problems is not always easy. Because the team are so far away from their suppliers across the world, they have had to adopt a can-do Kiwi attitude to get things done:

“… We teach ourselves how to apply the equipment. How to repair it and if necessary, modify it. We have a strong sense of self-sufficiency in all that we do. This allows us to be proactive in our approach to the customer’s needs rather than wait for a response from a distant supplier.”

This can-do attitude has helped Hyspecs keep up with the times and continue providing excellent service. They now have two dedicated departments in their NZ branches to apply electronics to improve the efficiency and controllability of their systems. Hyspecs’ sister company Hytech also enables them to provide vertical integration in the manifold market. The team can rapidly design and manufacture manifolds to specifically meet a customer’s needs:

“They have the opportunity to see a 3D model before we cut metal so they can see what the finished product will look like. Once the client is happy with this model, we proceed to the machining process. This whole process can happen rather quickly,” Richard said.

“Manifold technology is a powerful product giving OEMs [original equipment manufacturers], a key advantage in costs and product IP security, that traditional point to point design does not.”

What is next for Hyspecs?

Hyspecs has clearly found a recipe for success, one that we think is very similar to ours at Howick. Richard explains that they do not plan to reinvent the hydraulic wheel, but continue to improve and innovate on strong foundations:

“We plan to continue to grow our traditional hydraulics sales and to diversify into electronics and industrial automation. Growth through knowledge, service and integrity.”

As both Hyspecs and Howick continue to grow together it is clear that the reason the two businesses are such a great fit is their similarities. These are two NZ owned and operated businesses obsessed with quality and innovation, built on Kiwi ingenuity, who see their customers as long-term partners.

And like Howick, Hyspecs is well aware of what their greatest asset is:

“Our most notable milestones are hiring our brilliant people. It is their skill and dedication that makes us successful.”

Enjoyed this read? Spread the word by sharing below.

January 2025 #Features