ARKEO SYSTEM: Saidia Luxury Villas Guadeloupe

Guadeloupe

⏱️ 5 min read

Guadeloupe is an overseas region of France made up of a dozen islands in the Caribbean. It is famous for its sun-kissed beaches, but due to its remote location, steep terrain and cyclone prone, tropical climate, it can be a challenging place to build.

France-based construction company, ARKEO SYSTEM, recently overcame these challenges to design and manufacture a collection of four luxury villas using innovative construction methods and Howick’s precision steel roll-forming technology.

Introducing ARKEO SYSTEM

In 2018 Peiuko Pourquié and Jerome Lahure founded ARKEO SYSTEM, an innovative France-based business specialising in offsite light gauge steel construction. The founders have made it their mission to reduce the environmental impact of housing:

“Lightweight metal frames are the solution to accelerate the ecological transition of construction,” said Peiuko.

And so, with that goal in mind, they have driven the adoption of these new technologies throughout France. Their efforts are clearly working – we have previously featured another project of theirs, a luxury villa in the Basque Country where they used 3D modelling tools and the FRAMA™ 3200 to deliver a sustainable, cost effective solution that fits perfectly with the unique architectural style of the region.

The Saidia Villas project is another challenging project in a remote location.

The Project: Saidia Luxury Villas

The Saidia Villas are a collection of three 190m2 villas and one 260m2 villa. Each luxury residence includes a terrace with a private swimming pool, garage and refined living spaces.

When the ARKEO SYSTEM team first inspected the site they quickly realised it came with several challenges:

“Guadeloupe is in a cyclone-prone area, so it was essential that the construction solution should also be cyclone-resistant. The configuration of the terrain limited the positioning of lifting equipment, so the system also had to be manoeuvrable,” said Peiuko Pourquié, founder and president of ARKEO SYSTEM.

“Lightweight steel construction naturally emerged as the solution best suited to its specifications.”

ARKEO SYSTEM clearly knows what they’re doing. Cold formed steel is proven to be the ultimate solution for high-wind, flood prone, humid environments. Why? It has the highest strength-to-weight ratio of any framing material and it will bend and flex rather than crack and splinter.

How ARKEO SYSTEM steels success with Howick machines

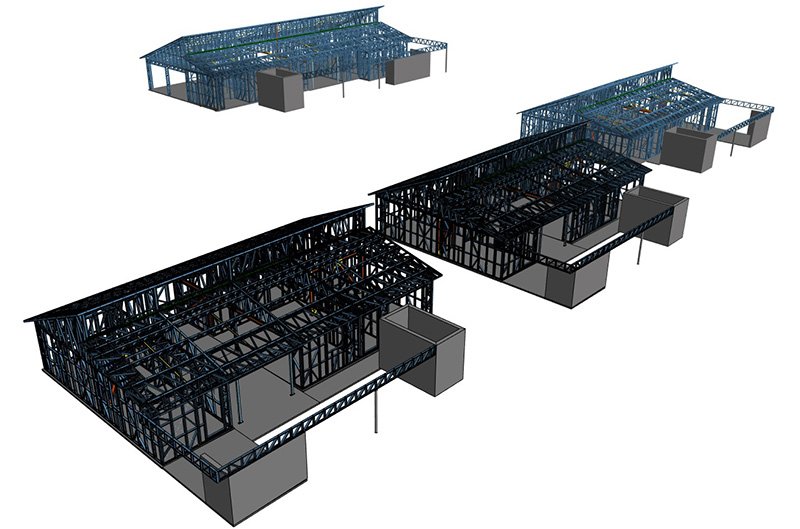

To start, ARKEO SYSTEM 3D modelled the entire development using Vertex Building Information Management (BIM). The system integrated perfectly with the Howick machine, which connected to the 3D model to automate production of every component with millimetre precision:

“It’s reassuring for a design manufacturer like ARKEO SYSTEM to be certain that what is designed by our design department will be manufactured by our production department just as it was designed. This allows us to highlight the precision of the FRAMA 3200™ machine.”

Once design was completed, the first villa was manufactured and shipped entirely in panels, while the framing for the following three villas was delivered in bundles. As per ARKEO SYSTEM’s usual process, the building package included a detailed assembly plan:

“This made-to-measure packaging meant that the first villa could be built more easily from pre-assembled panels, then the other 3 villas in bundles helped to limit freight costs,” Peiuko explained.

“ARKEO SYSTEM also trained the local teams by sending a specialist to help local professionals get to grips with the system and the detailed assembly instructions.”

Because light gauge steel panels are so lightweight, they could be moved and assembled by a small team of installers and manoeuvered easily on the steep site.

Once the components arrived the hard work is already done. The Howick machine cuts each panel to length and pre-punches them with millimetre accuracy, meaning there’s no need for any onsite adjustment. There’s also no waste produced onsite and the finished product is extremely durable.

The client obviously appreciated ARKEO SYSTEM’s ability to overcome the project’s difficulties:

“Our customer was won over by our innovative construction method, which is solid, light and quick to install.”

“ARKEO SYSTEM’s ongoing support and flexibility in execution enabled us to create a relationship of trust with our client. And it was undoubtedly this added value that turned this challenge into a success.”

Due to ARKEO SYSTEM’s use of BIM systems and the Howick machine, the process was extremely quick. The entire structure of the four villas was produced and partly pre-assembled in less than two months, and the first villa was assembled within three weeks.

Benefits delivered

- Very strong, lightweight construction

- A high level of precision in all structures thanks to the Howick FRAMA™ 3200

- Simplicity of assembly thanks to ARKEO’s smart design and Howick technology

- Zero waste onsite

- Extremely fast build times - first villa assembled within three weeks

- Minimal labour required for assembly

Was this case study insightful? Share it